Lots of free features

All the features your business requires without the need for specific training. Easy to set up and use.

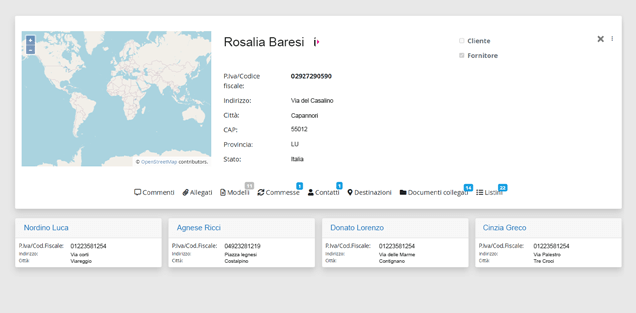

All important contacts for your company always available, updated and verified thanks to the real-time connection with European databases. Easily import your contacts from your phone’s address book as well.

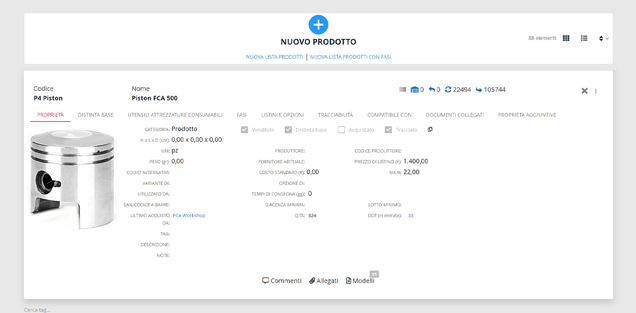

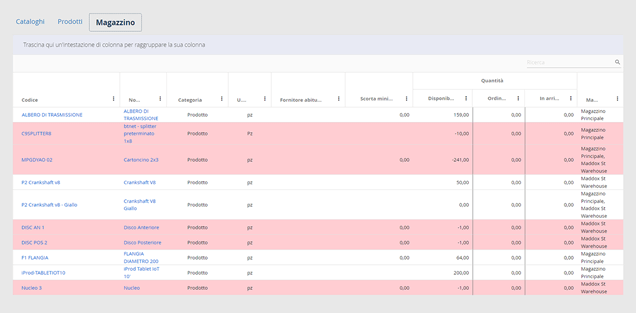

Create a complete card for each of your products by defining, with a simple wizard, drawings, raw materials, semi-finished products and production cycles. Associate drawings, attachments, photos and videos directly from your mobile phone or computer.

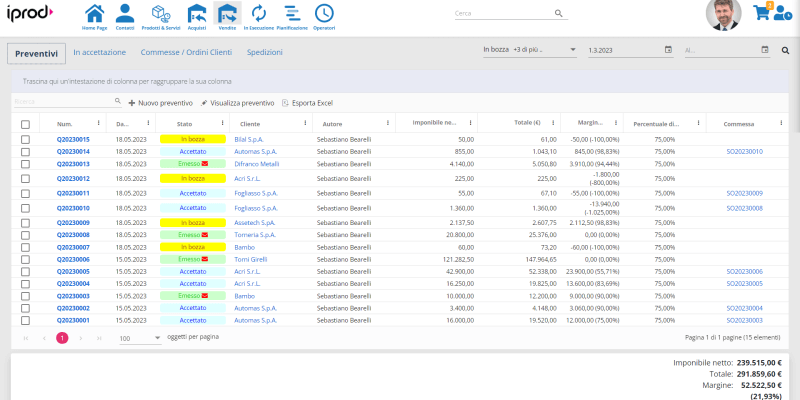

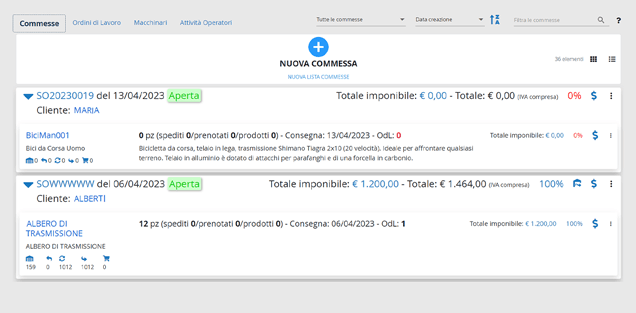

Automatically create ERP documents of products bought and sold on the Marketplace or any other distribution channels. Real time stock updates through the documents generated.

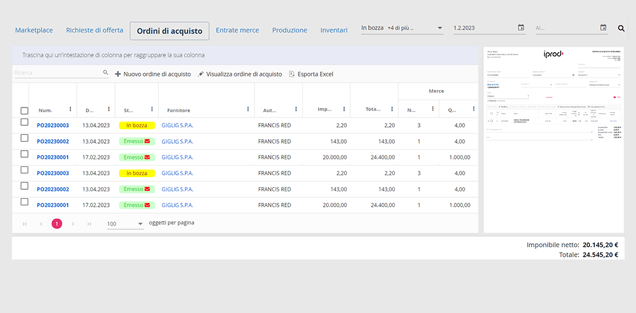

Create and print incoming goods documents and purchase orders.

Make offer requests to send to your potential suppliers, compare quotation received and plan your purchases

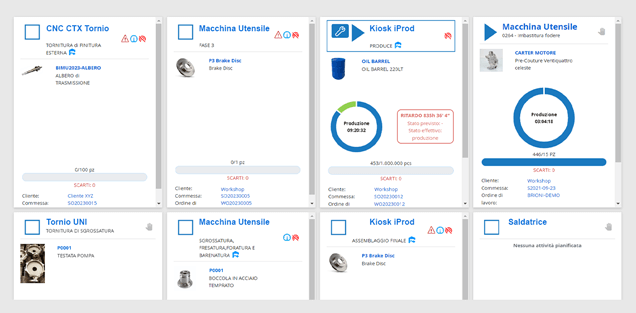

Create work orders for each of your sales orders and monitor in real time every production phase for each machine and the activities in execution. Keep track of the progress of orders thanks to the automatic detection of finished products, scraps, processing time, costs, alarms and downtime via App or IoT Tablet.

Economic forecasts of profitability and costs of individual orders are provided thanks to the processing of data such as material costs, times and costs per operators and machines.

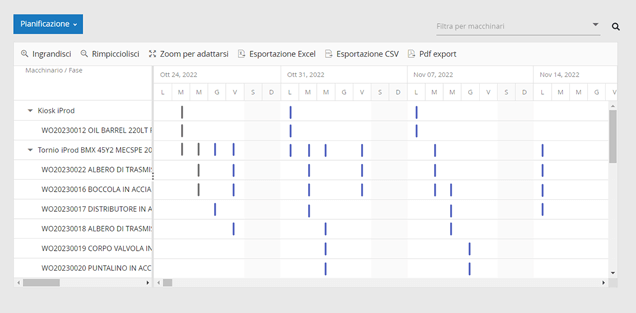

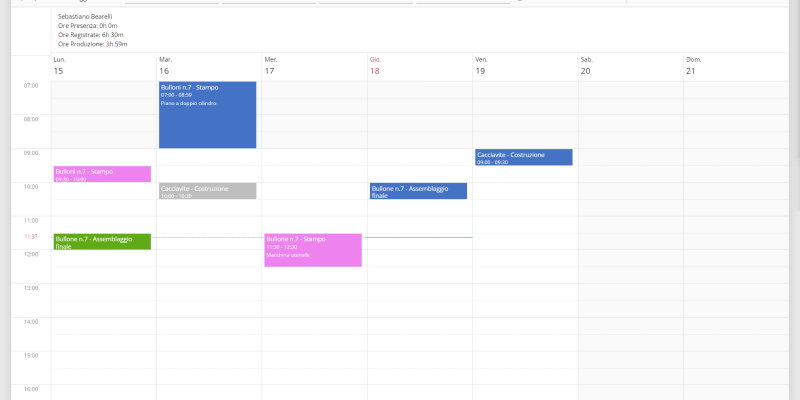

Schedule machine activities, human resources, staff times and tasks. The operator knows to which machine it has assigned and which activities (Orders, Work Orders) must be done.

A operations management solution for tracing the supply chain: from your warehouse to delivery.

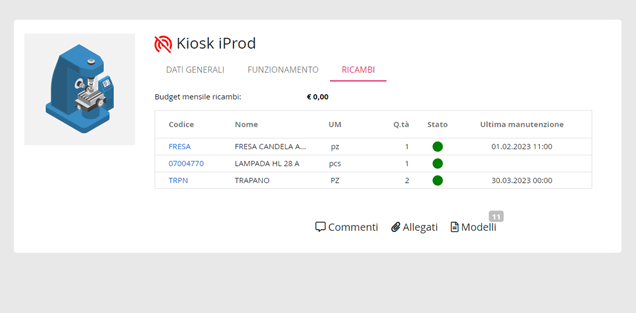

Simplify maintenance management process. Collect fault reports, tickets will be assigned to staff with the information they need, track and monitor their progress in real time.

Organize machinery activities, staff tasks and view the calendar of production activities.

The operator knows to which machine it has assigned and which activities (Orders, Work Orders) must be done.

Il potenziale di iProd per la vostra azienda

+15%

10

3.6MLN

What makes us stand out

Facets

Features

Our Partners

Who chose us

Who chose us

Piano Transizione 5.0 e Credito di imposta

Recover up to 50% of your investments in machines, devices, equipment and software for the technological and digital transition of your business.

La soluzione iProd è predisposta per ottenere i benefici fiscali 2017-2025 del Credito d'Imposta per investimenti 5.0, grazie all’interconnessione bidirezionale tra le macchine e device, rendendo così possibile l'accesso ai benefici fiscali del Piano Transizione 5.0. Puoi contare sulla certificazione 5.0 anche grazie alla convenzione di iProd con ICIM, l'ente di certificazione leader in Italia.

Contact us for a free consultation.

Are you looking for specific answers?

You can find them in our Knowledge Base or contact us to learn more

Project: iProd AI

The "iProd AI" project involved the enhancement of the multitenant cloud SaaS platform with advanced technologies of Artificial Intelligence, Cybersecurity, IoT and Cloud Computing, aimed at promoting the digital transformation of manufacturing companies.

Project co-financed by the PR FESR TOSCANA 2021 – 2027 Action 1.1.3 - Call "Digital Enterprise" – Services for Innovation

Call Approved with D.D 18182 of 21 08 2023

Decree of Admission to Contribution n. 56 of 14.05.24

Project implementation period: 2023–2025

Financial support received: € 34,840.00

Progetto: iProd AI

Request CUP : 14630.30062023.037032203_1504